Full Sphere Jet Nozzle

Product Details:

- Operating Pressure 110 bar

- Pressure 110 bar

- Air Consumption 0.05 to 0.8 m/min (at 6 bar), depends on orifice size

- Capacity Up to 120 L/min (at optimal pressure)

- Thread size 1/4 to 2 BSP/NPT

- Diameter Varies by nozzle size (from 5 mm to 40 mm)

- Air Inlet Threaded connection BSP/NPT

- Click to View more

X

Full Sphere Jet Nozzle Product Specifications

- 360 Spherical Spray Pattern

- Stainless Steel 304/316, Brass

- 1/4 to 2 BSP/NPT

- Varies by nozzle size (from 5 mm to 40 mm)

- Industrial, Dust Control, Cooling, Washing, Humidification

- Up to 120 L/min (at optimal pressure)

- Threaded connection BSP/NPT

- 1/4 to 2 BSP/NPT

- Stainless Steel, Brass

- 0.05 to 0.8 m/min (at 6 bar), depends on orifice size

- 110 bar

- 110 bar

- Full Cone Spray Nozzle (Full Sphere Jet Nozzle)

Product Description

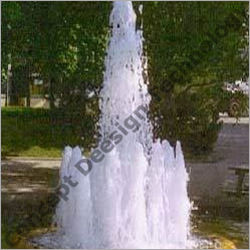

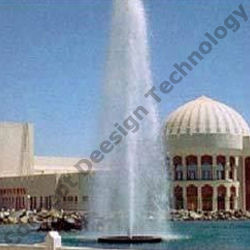

Being a client centric organization, we offer an ample range of Full Sphere Jet Nozzle to our clients. These are provided in the ball size of 6" / 10" / 12" and high recognized for its efficiency and contemporary look. Apart from this, our clients can avail these nozzles at market leading rates- Model:CDT-FSJ-11

- Ball Size : 6" / 10" / 12"

- Inlet Size : 100mm

- Body : Gunmetal with Crome plated.

Comprehensive 360 Spray Coverage

Designed to deliver a full cone, spherical spray pattern, the Full Sphere Jet Nozzle ensures complete coverage for efficient washing, dust control, cooling, and humidification. The 360 spray is ideal for enclosed or hard-to-reach spaces where uniform liquid distribution is essential.

Adaptable and Durable Construction

Available in stainless steel and brass, this nozzle excels in both durability and corrosion resistance. With a temperature tolerance up to 300C (dependent on chosen material) and a customizable orifice size, it effectively meets specialized industrial requirements in harsh processing environments.

Simple Installation and Maintenance

The threaded mount accommodates both vertical and horizontal installation, compatible with BSP/NPT standards. Regular maintenance is hassle-free due to its easy disassembly, supporting continued high performance in demanding industrial operations.

FAQs of Full Sphere Jet Nozzle:

Q: How is the Full Sphere Jet Nozzle installed?

A: The nozzle features threaded BSP or NPT connections, allowing for easy installation in either vertical or horizontal orientations. Simply screw it into compatible mounting points, ensuring a secure fit for optimal spray performance.Q: What materials are available for this nozzle, and how do they benefit specific applications?

A: The nozzle is available in stainless steel 304/316 and brass. Stainless steel offers excellent corrosion and temperature resistance for aggressive environments, while brass is suitable for lower-temperature or less corrosive conditions. Choose the material best suited to your industrys needs.Q: When should I opt for a customized orifice size?

A: Customized orifice sizes (from 1.5 mm to 12 mm) are beneficial when specific flow rates or spray coverage are required. Selecting the right size ensures efficient liquid distribution tailored to application-specific requirements, such as dust suppression or food processing.Q: Where can this nozzle be used?

A: It is suitable for various industries, including chemical processing, food & beverage, dust control, odor management, fire protection, cooling, washing, and humidificationanywhere a consistent 360 spray is required.Q: What is the process for maintaining and cleaning the nozzle?

A: Maintenance is straightforward. The nozzle can be easily disassembled without special tools, allowing for quick cleaning and removal of potential blockages, which helps maintain steady performance.Q: How does the Full Sphere Jet Nozzle benefit industrial operations?

A: Its robust construction, high temperature resistance, and full 360 spray pattern ensure effective liquid dispersion, improve process efficiency, minimize downtime due to easy cleaning, and enhance safety in demanding settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Nozzles' category

Registred Office:

L/121, Street No. 3,

Gautam Vihar, New Delhi.

|

CONCEPT DEESIGN TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |